In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

Understanding Centering Clamps

Centering clamps, also known as engineering clamps, are indispensable tools in various industries where holding workpieces securely and precisely is essential. Traditionally, clamping mechanisms required meticulous adjustments to ensure proper alignment, often leading to time-consuming setups and adjustments. This is where self-centering clamps step in to revolutionize the game.

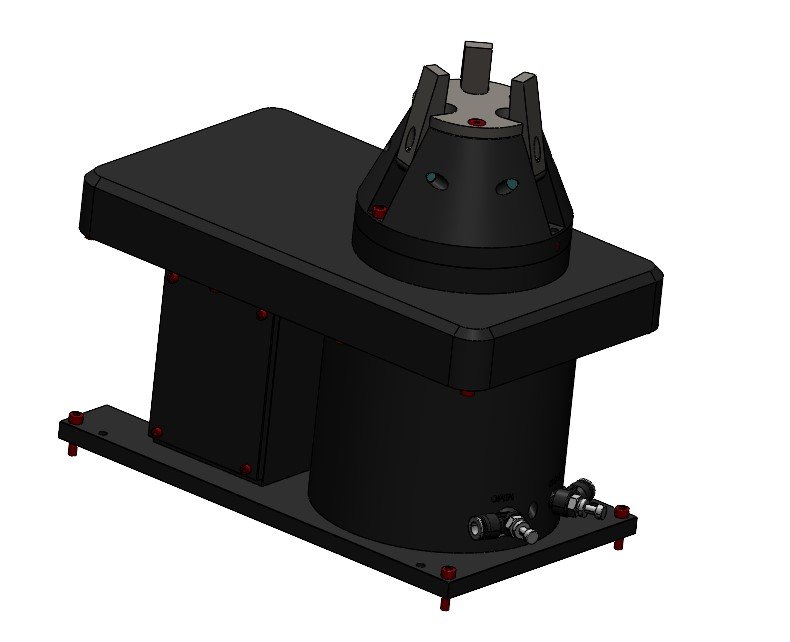

Unyielding strength in every grip. The JE heavy-duty Work Station is built to handle 1000+ pounds with ease.

Enter Self-Centering Clamps

Self-centering clamps stand out as a beacon of innovation in the realm of workholding solutions. These ingenious devices are designed to automatically center and secure workpieces with lightning-fast precision, eliminating the need for manual adjustments. This "quik-change" feature ensures lightning-fast change-outs, significantly reducing setup time and increasing productivity.

Time-Saving Benefits

Time is money, especially in the competitive landscape of manufacturing. With traditional clamping methods, precious minutes are spent on meticulous adjustments to achieve the desired alignment. Self-centering clamps, on the other hand, drastically reduce setup time by automatically centering the workpiece with unparalleled speed and accuracy. This means engineers and machinists can devote more time to actual production tasks, maximizing efficiency and output.

Labor Advantages

Labor optimization is another crucial aspect of any manufacturing operation. By incorporating self-centering clamps into the workflow, companies can streamline their processes and make more efficient use of human resources. With reduced setup times and simplified operation, skilled workers can focus on tasks that require their expertise, rather than repetitive manual adjustments.

Versatility and Reliability

Self-centering clamps are renowned for their versatility and reliability. See multiple versions here.

Whether in CNC machining, welding, assembly, or any other application requiring precise workholding, these clamps deliver consistent performance, ensuring repeatable results with minimal effort.

Conclusion

In conclusion, self-centering clamps represent a significant leap forward in workholding technology. Their ability to provide lightning-fast change-outs, coupled with the time-saving benefits and labor advantages they offer, make them indispensable tools in modern manufacturing environments. By embracing innovation and efficiency, companies can stay ahead of the curve and unlock new levels of productivity in their operations.