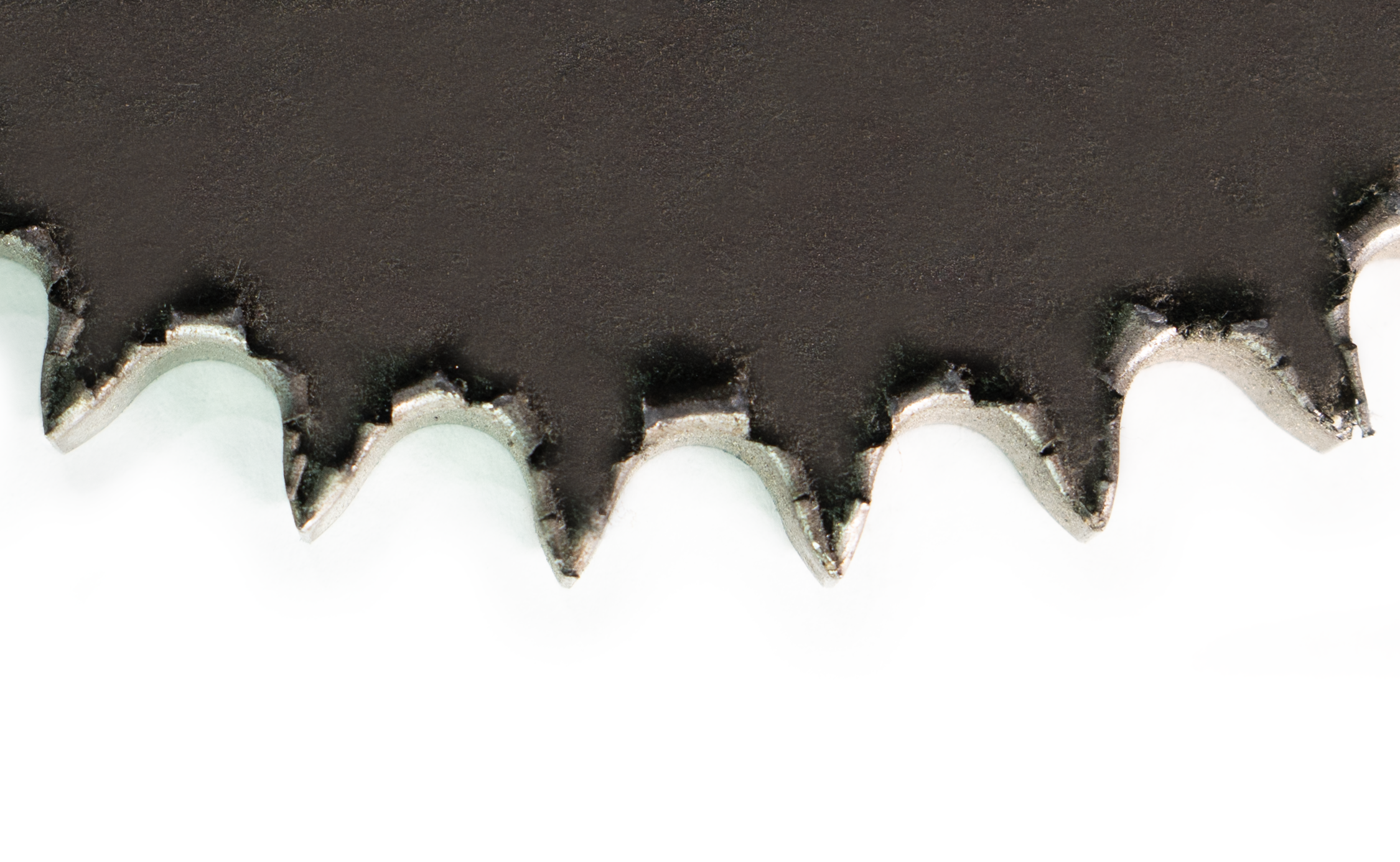

Gear sprockets

Gear Sprockets pose a unique challenge when it comes to finishing them properly.

These big-or-little gears require intense attention to detail, which is vital for their function, but time consuming and costly. Normally, a sprocket would have to be deburred, chamfered, and brushed by hand deburring or in a manual deburring machine. These options are fine in some scenarios, but for a production business, these options will ultimately slow you down and disrupt the flow of operations.

An automated deburring machine such as The MAX System greatly outpaces any manual and hand operations, especially when sprockets are involved. The MAX will process a sprocket of any size in up to 10 seconds. Two major features of the MAX allow for this amazing processing time: its capabilities to run multiple tools concurrently, and its ability to program part adjustments for future use.

The recipe programming of the MAX singlehandedly makes it a standout deburring machine. It will take operators anywhere from 5 to 10 minutes to adjust the deburring machine to a specific part, and once they have, the MAX will remember said adjustments and save them for future use. It can save a multitude of different part recipes, making it ridiculously easy to change out parts, no matter how drastic size differences/requirements are between them. Because sprockets are such tricky parts, this saves businesses an abundance of precious time.

The MAX also offers both wet and dry options. The deburring machine will run beautifully either way, so it’s ultimately a matter of preference. However, the wet option is fantastic if you’re worried about flammable debris and how it can affect your machine. The wet MAX comes with rust-inhibiting solution so as to not damage machine or part, and it quickly washes away any debris before it becomes an issue. No debris will ever get caught between the teeth of sprockets of any size.

Gear Sprockets can be a manufacturer’s nightmare, but they don’t have to be. The MAX System by James Engineering is built with efficiency and precision in mind, meaning it can take any sprocket with ease.

Watch the video below to see how all of this works in real-time.

Deburring Various Gear Sprockets in seconds with ease with the ultimate deburring machine