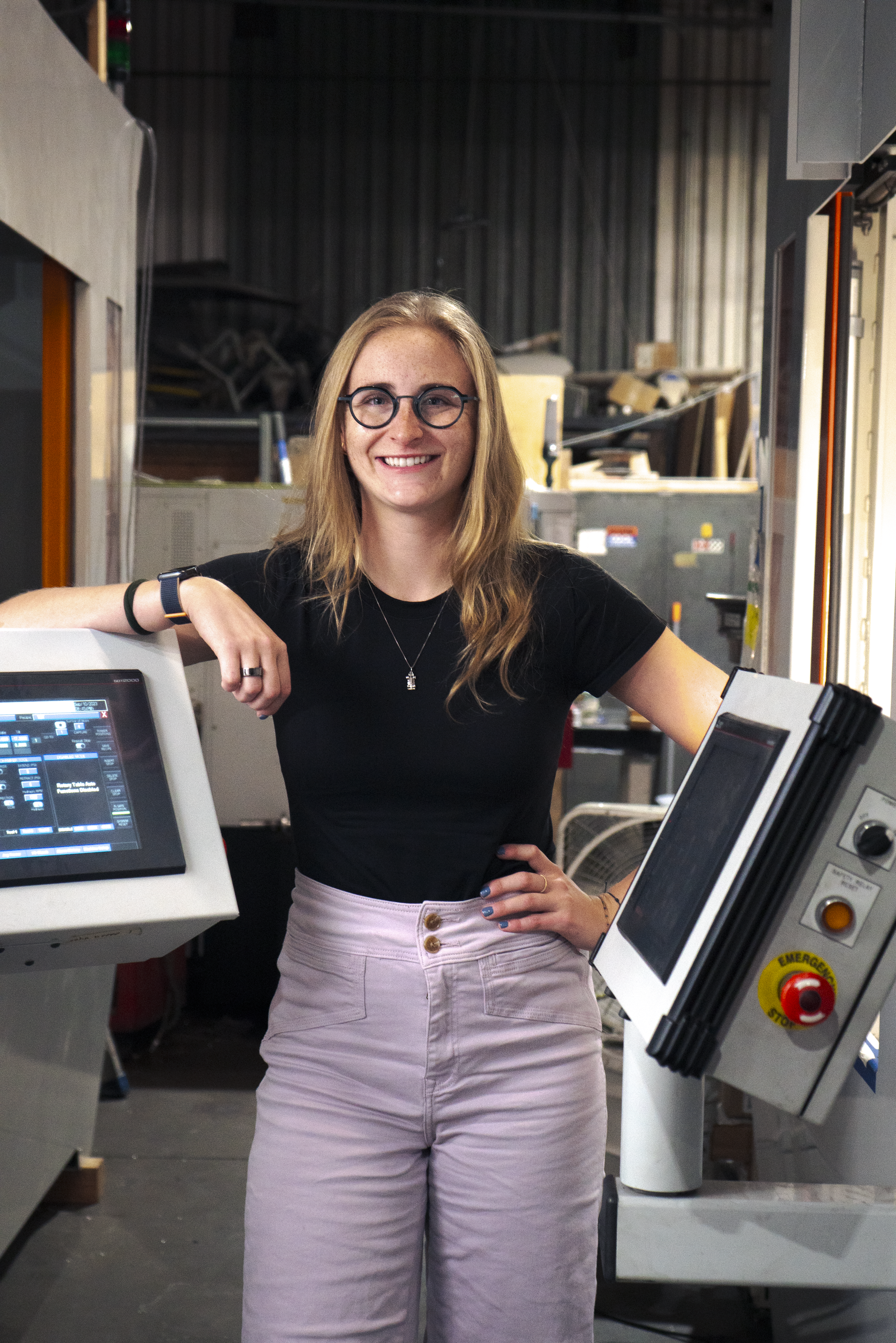

Fluttering between the stone halls of CU Boulder and the bustling shop of James Engineering, Quinn Gossett studies hard and works even harder. Shortly after finding out about the family-owned OEM shop through a friend, Gossett began her job as a mechanical engineering intern—the perfect gig for a mechanical engineering undergrad.

“I chose to study engineering because it is the perfect combination of creative problem solving and science, two things I love,” explains Gossett. “Oftentimes there are several ways to solve a problem, and that requires truly creative thinking, which is something I’ve done naturally my whole life.” Gossett quickly slipped into her role at James Engineering, tackling any challenges presented to her with a fresh-faced eagerness. “One of the first obstacles I faced was establishing a system of organization for myself. The machines that [we] build are very complex. I was able to overcome that challenge by being thorough and asking questions as soon as they came up.”

But by pushing through and solving these challenges, Gossett gained expansive hands-on experience which wound up giving her an in-depth look at the engineering career field.

“My work [at James Engineering] stretched me outside what is traditionally considered mechanical engineering. I worked on project management, component design, and [even] hands-on assembly and manufacturing. Since James Engineering is a small company, there is ample opportunity to work in these different areas. Not having a hyper specific specialization has allowed me to develop a well-rounded set of skills.”

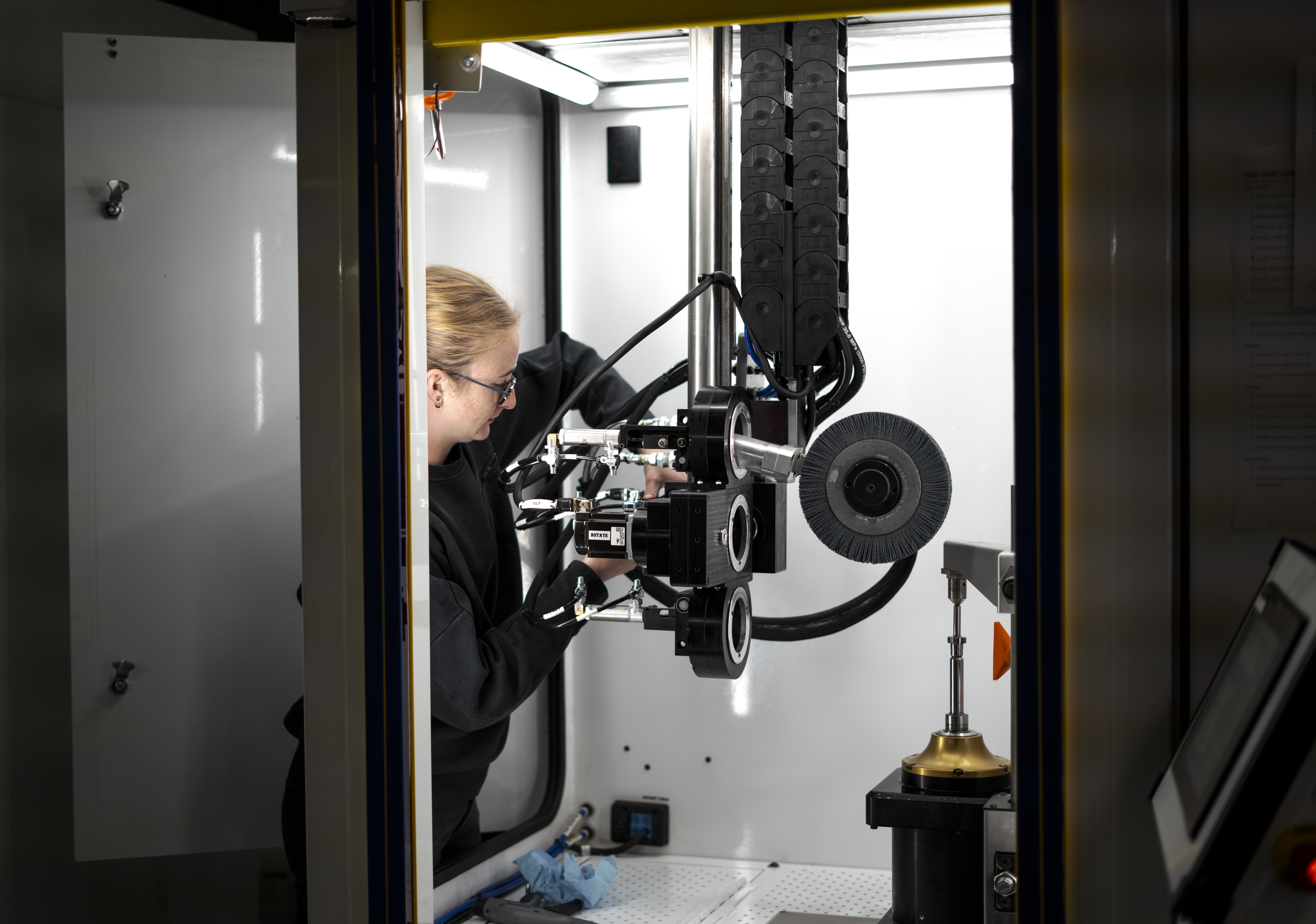

Gossett expanded upon her project management skills by creating systems that tracked the building process of specific machines. These systems revealed any problematic dependencies to the team of engineers, while also providing them with clues as to how to make the building process more efficient. Before building could even really start, however, Gossett had to go through the trials-and-errors of component design process. Seamless component design is crucial, which Gossett discovered, especially since she had to figure out how to incorporate new parts into already-existing assemblies. “It was necessary to explore multiple design options instead of immediately committing to one design for full development,” she writes. Once a component was correctly designed, the assembly process could begin, which allowed Gossett continuous hands-on involvement. Gossett then discovered that assembly can show intricacies that her CAD models can’t, further enhancing her knowledge when it comes to designing new parts.

"Developing skills across several disciplines changed my perspective on how the engineering process works as a whole,” Gossett continues, “Even when working on one individual component, it is critical to understand what it takes to manufacture the part.”

James Engineering constantly encourages continued learning when it comes to the engineering industry—both for the new and the experienced. Just one internship or job opportunity can completely change an engineer’s perspective of the industry and teach them something new they wouldn’t have been able to garner anywhere else. After her time at James Engineering, Gossett offers some advice to those interested in becoming mechanical engineers themselves:

“Be prepared to work hard and work creatively. There are times where you will fail, but that is part of the learning process. The mechanical engineering curriculum reaches across a wide range of disciplines and is extremely well rounded, [so] as long as you are trying your best, that will get you far.”

Mechanical engineering is a stimulating and rewarding industry that always asks the question, “How can this be better?”. As engineers design practical, efficient, and complex solutions to the multitude of problems that pop up in our everyday lives, it’s important for them to remember how their work impacts the world around them. “My biggest goal is to leave this world better than I found it. Through any industry I work in, I always want to use my skills to create solutions that make this world a better place for every human and every creature that calls Earth their home.”

Gossett has already succeeded at making James Engineering a better place.

To all the engineering students out there, we at James Engineering commend your dedication and inspiration—it is a rigorous industry, but it is worthwhile. If you are interested in learning more about James Engineering and how we contribute to the mechanical engineering industry, click here to check out the rest of our website. In the meantime, keep studying, keep creating, and keep innovating.