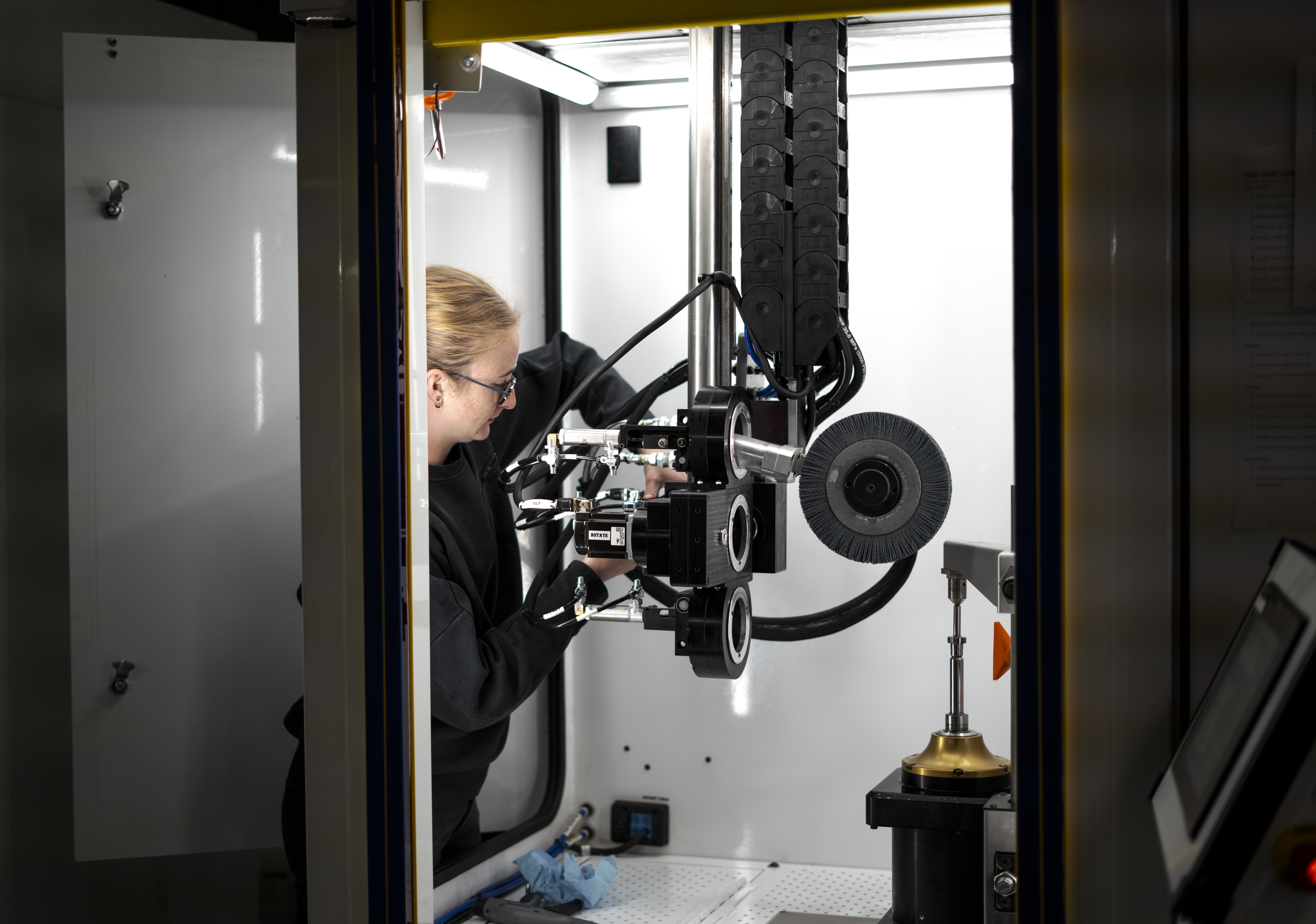

Understanding Gear Hobbing and Deburring in Manufacturing. What is Gear Hobbing? Gear hobbing is a machining process used to cut gears, splines, and sprockets. What is the Difference Between Gear Cutting and Hobbing? Why is it Important to Remove Burrs? What is the Effect of Deburring?

We answer ALL your questions!